- Overview

- Scour velocity

- System Flushing

- Storm tank draining

Storm Tank Cleaning

Overview

Computational Fluid Dynamics (CFD) is ideally suited to provide an assessment of the self-cleansing characteristics of storm storage tanks. The analysis can abstract velocity data and profiles, whilst studying the effectiveness of various wash water systems. The analysis can study various water levels and types of wash water plant with a view to optimising tank cleansing.

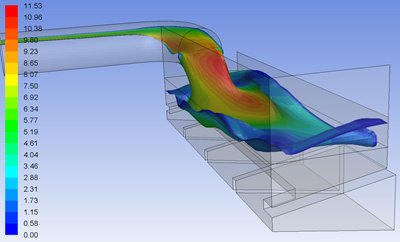

Scour velocity

The CFD analysis determines velocity profiles throughout the structure over a comprehensive range of operating scenarios to allow a detailed assessment of the self-cleansing characteristics. Such data can be presented as streak lines or contours plots to determine flow paths and velocity gradients.

System Flushing

CFD analysis can be used to provide a dynamic simulation of system flushing, such as vacuum tanks and tilting bucket type applications. The wave effects characterised by this type of system can be accurately replicated by CFD analysis to give a real time simulation of tank cleaning.

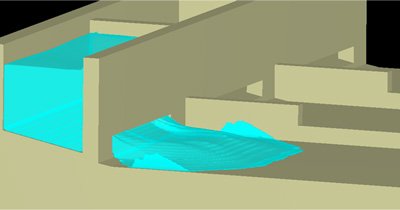

Storm tank draining

On the cessation of the storm event and subsequent draw down of the storm tank, the CFD analysis allows identification of potential regions of deposition, which may not be cleared during the wash water cycle. Identification of these potential areas of deposition is critical to ensure that during the next phase of tank cleaning the solids accumulation is cleared. CFD analysis allows optimisation of the tank design to minimise potential for deposition under all phases of tank operation.