Overview

Inlet works are complex hydraulic structures and may comprise screens, grit removal systems, bypass and overflows. The satisfactory operation of each element of an inlet works is dependent on the hydraulic profile in order to maintain acceptable velocities, head losses and satisfactory flow presentation. Physical modelling provides an assessment of the hydraulic performance of an inlet works; this is summarised in the following topic areas:-

- Flow distribution

- Hydraulic profile

- Storm overflows

- Flow control devices

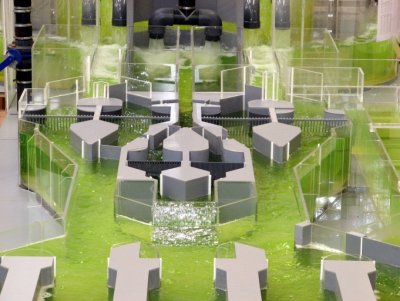

Flow distribution

Achieving acceptable flow and velocity distribution can be critical for plant such as screens and grit removal systems. Failure to achieve acceptable flow distribution can lead, typically on screens, to velocity concentration at the screen element (face) with consequential uneven hydraulic and solids load across the screen.

In the case of grit removal basins, such as detritors, poor flow distribution across the basin can lead to scour of grit type debris from one side of the basin and conversely retention of organics and lighter inorganic solids to the opposing side. Empirical testing of detritor grit settlement basins on a physical model can yield significant improvements in flow distribution by, for example, the determination of optimum vane pitch at a detritor basin inlet.

Hydraulic profile

A physical model will accurately reproduce velocities, hydraulic gradients and head losses within a system.This allows a comprehensive assessment of the hydraulic grade line to be determined through each of the individual elements of the inlet works. Water level measurements are undertaken with piezometric tapings and comprise the upper limit of the intermittent and top water surface. Confirmation of the hydraulic profile is essential to verify the overall concept design and ensure effective plant operation.

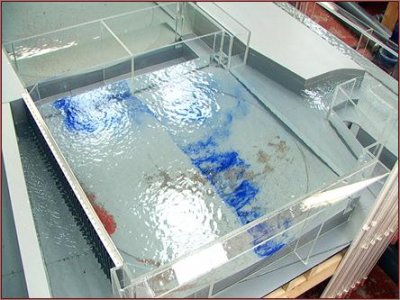

Storm overflow

Storm overflows are provided within an inlet works to ensure that flow in excess of the design Flow ForTreatment (FFT) does not overload the treatment process. A physical model can readily define the position, elevation and length of weirs required to achieve effective conveyance of storm flows. The physical model can accurately study the behaviour of all phases of solids i.e., positive, neutral and negatively buoyant particles within the system.This allows assessment of the solids transport, division and settlement during simulation of a typical storm cycle within the works.

Flow control devices

Standing wave flow control devices, such as flumes, are commonly used on inlet works as a method of controlling and measuring flow. Where devices of this type cannot be installed, typically due to site constraints, a physical model can readily develop and calibrate 'bespoke' flow control modules.