Temple Street CSO

Client: NORTHUMBRIAN WATERScale: 1/9th

The proposedTempleStreet CSO screening facility comprises of two sets of twin Huber Rotamat type RoK 2 screens. The station will pass a DWF of 140 l/s and reach a peak inflow of 9000 l/s for both free discharge (low tide) and surcharge (high tide) conditions. he station has being designed to contain a 1 in 5 year event.

At DWF conditions crude, unscreened sewage will pass though the system to treatment. In the event of a rising storm, a maximum pass forward flow of 540 l/s will be sent to treatment, controlled by a modulating penstock downstream of the screens. With the water level in the station rising, the additional flow will be screened and passed over the overflow weirs for discharge to the River Tyne.

Initial testing

Initial testing studied a range of inflows from DWF up to the one in forty year inflow of 9000 l/s. The CSO has been designed to screen up to a one in five year flow of 8200l/s, inflows in excess of this value are permitted to overtop the screens and spill via the relief weir and screen vent weirs.. Initial testing of the screening facility was undertaken with the relief weirs set at an elevation of 6.660 mAOD with the screen vent weirs set at 0.60 m and spill weirs set at 6.060 mAOD.

Testing showed that an inflow of 6000 l/s could be contained by the vent weirs at an elevation of 6.060 mAOD with the relief weirs starting to be overtopped 8000 l/s

Development

To contain flow at 8000 l/s, both the vent and relief weirs had to be raised to a common level of 6.810 mAOD thus ensuring that the station would be able to contain the 8000 l/s without prematurely overtopping the weirs.

Final Testing

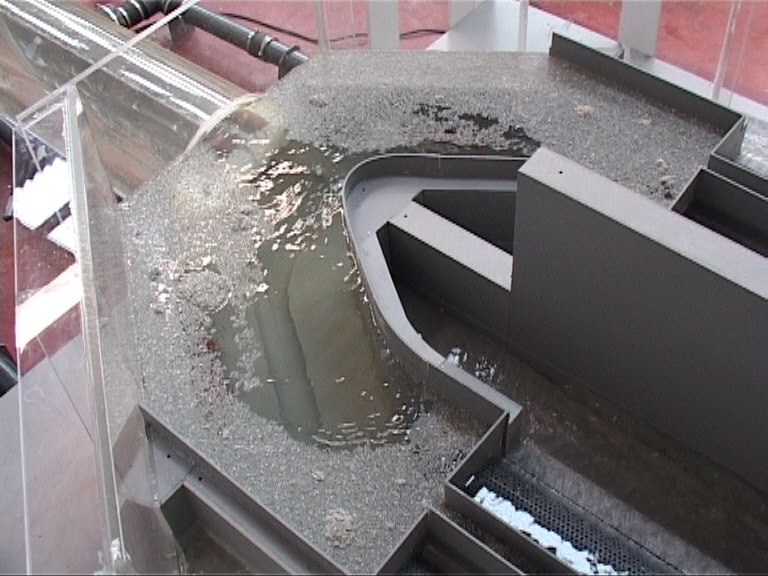

Final testing showed good hydraulic performance of the CSO. Flow was apportioned quite well to the two pairs of screens with flow utilising the full length of each screen assembly. Sub-critical flow conditions were maintained in the screen chamber across the anticipated inflow range. While surface turbulence was generated in the forebay and around the upstream faces of the vent weirs, at no stage was the turbulence considered to be detrimental to screen performance.

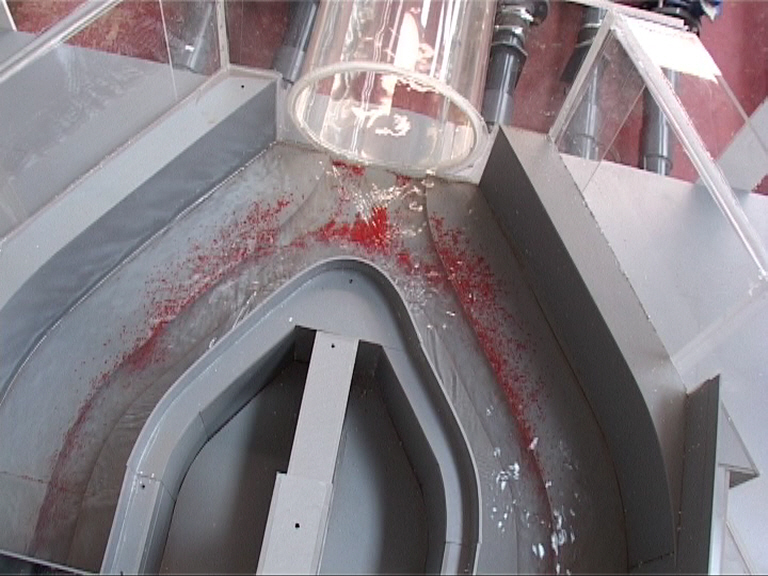

The behaviour of grits and floating debris was also investigated. Testing showed that the negative buoyancy debris, grit, had good transport through to the continuation pipe under most of the inflows with only a slight area of deposition noted on the sloping benching in the forebay. While this area of deposition was continually being agitated and cleared through to the continuation pipe, consideration may be given to modifying the profile of the benching to minimise deposition, see Section 3.5 of the report. Positive buoyancy debris under the various inflows had good transport to either of the screens, under a high inflow, or through to the continuation pipe under 540 l/s (the design pass forward flow.)

Water levels were measured for a range of inflows. At the 1 in 5 year event, with clean screens, a water level of 6.70 mAOD was recorded in the forebay. Conditions were also observed in the event the screens became fully blinded, under which case flow would be discharged over the vent and relief weirs. Simulating this on the model showed that a peak water level of 7.035 mAOD would be generated in the inlet forebay.