RIVER STRULE ABSTRACTION PUMPING STATION

Client: HYDER CONSULTINGScale: 1/3rd

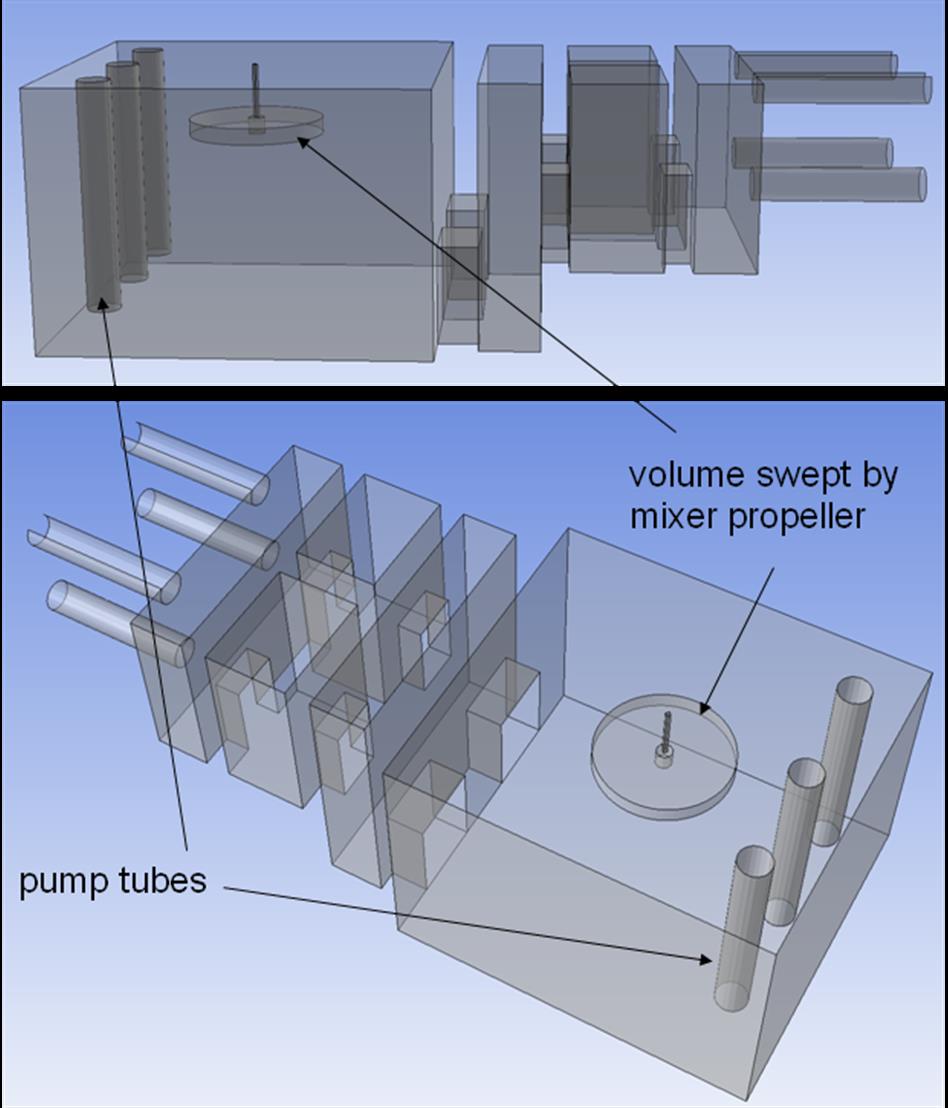

It was proposed to construct a new Pumping Station that will abstract water from the River Strule and pump raw water to the Derg Water Treatment Works. Flow to the Pumping Station will be delivered via two twin inlet pipes which discharge through twin band screens. Flow from the band screens will discharge via a ported baffle chamber directly in the sump chamber.

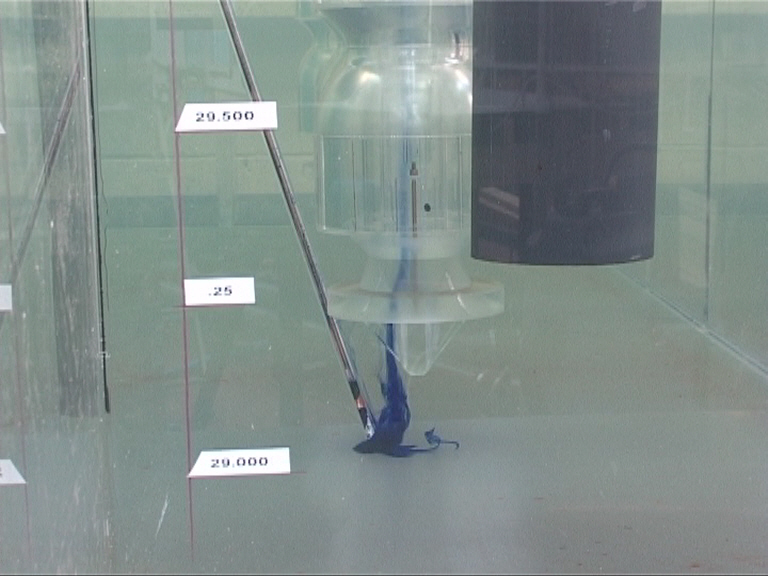

The Pumping Station included three vertical shaft pumps; each pump was capable of delivering between 80 l/s and 154 l/s. The pumps operated on a duty, assist and standby basis with two pumps capable of delivering 308 l/s. The Pumping Station also included a re-suspension mixer to help reduce sedimentation in the sump.

Initial testing

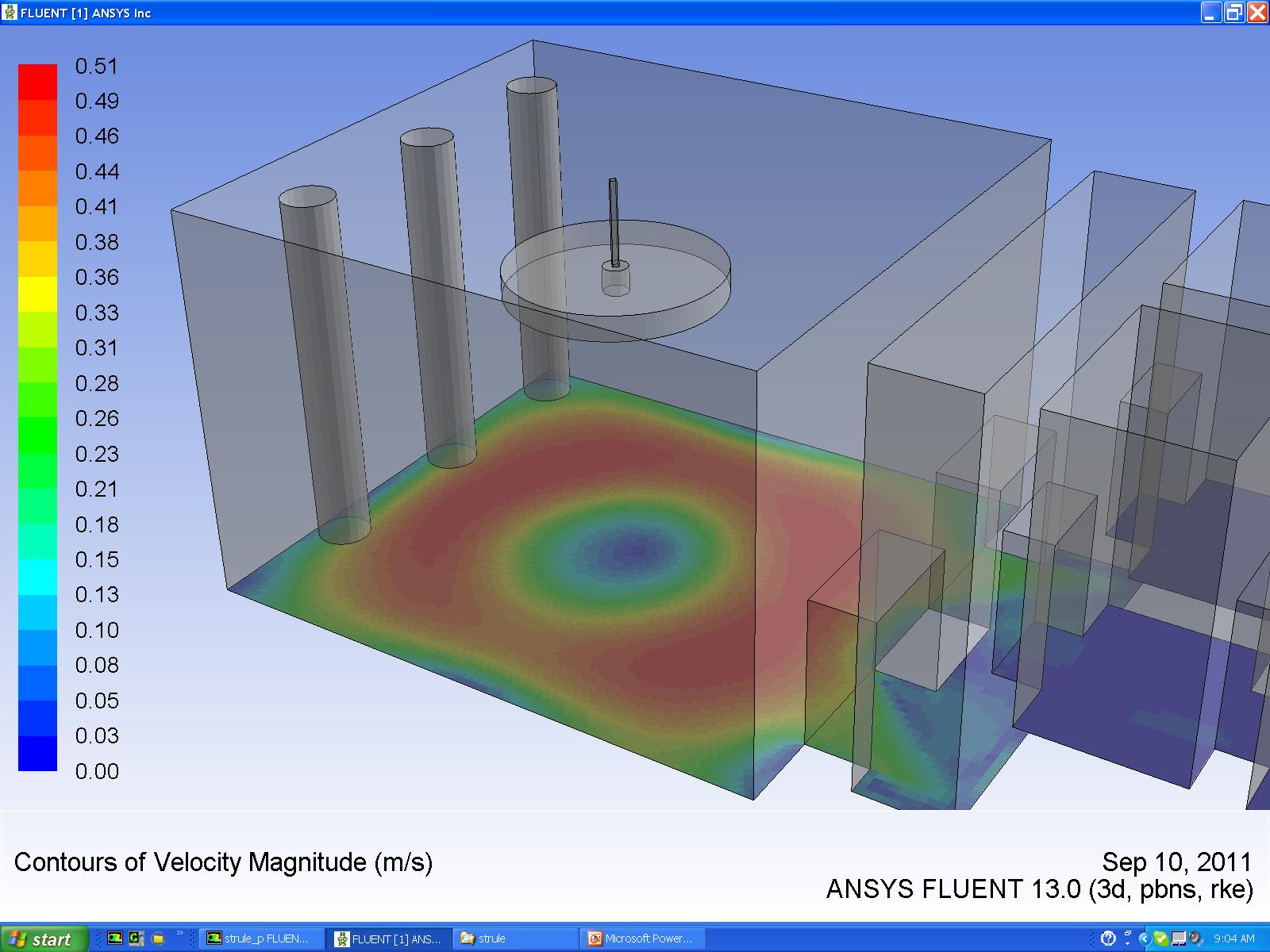

The initial testing programme determined that the Pumping Station design was considered acceptable with only minor adverse hydraulic phenomenon noted. The observed submerged vorticity between the sump floor and the pump suctions was not ideal with accelerated mechanical wear and pump vibration possible. In addition to the adverse conditions, two low velocity areas were identified at the corners of the main sump local to the ported baffle wall. Settable solids will deposit within these areas with very little movement to the pump suctions.

As part of the initial testing programme, an assessment of settable solids entering the station was undertaken. Large areas of solid deposition was observed on entering the main sump immediately after transport through the ported baffle wall, the noted deposition was a direct result of the sudden reduction in forward velocities within the large operating volume of the main sump. The noted area of deposition was evident regardless of sump operating volume and pumped outflow.

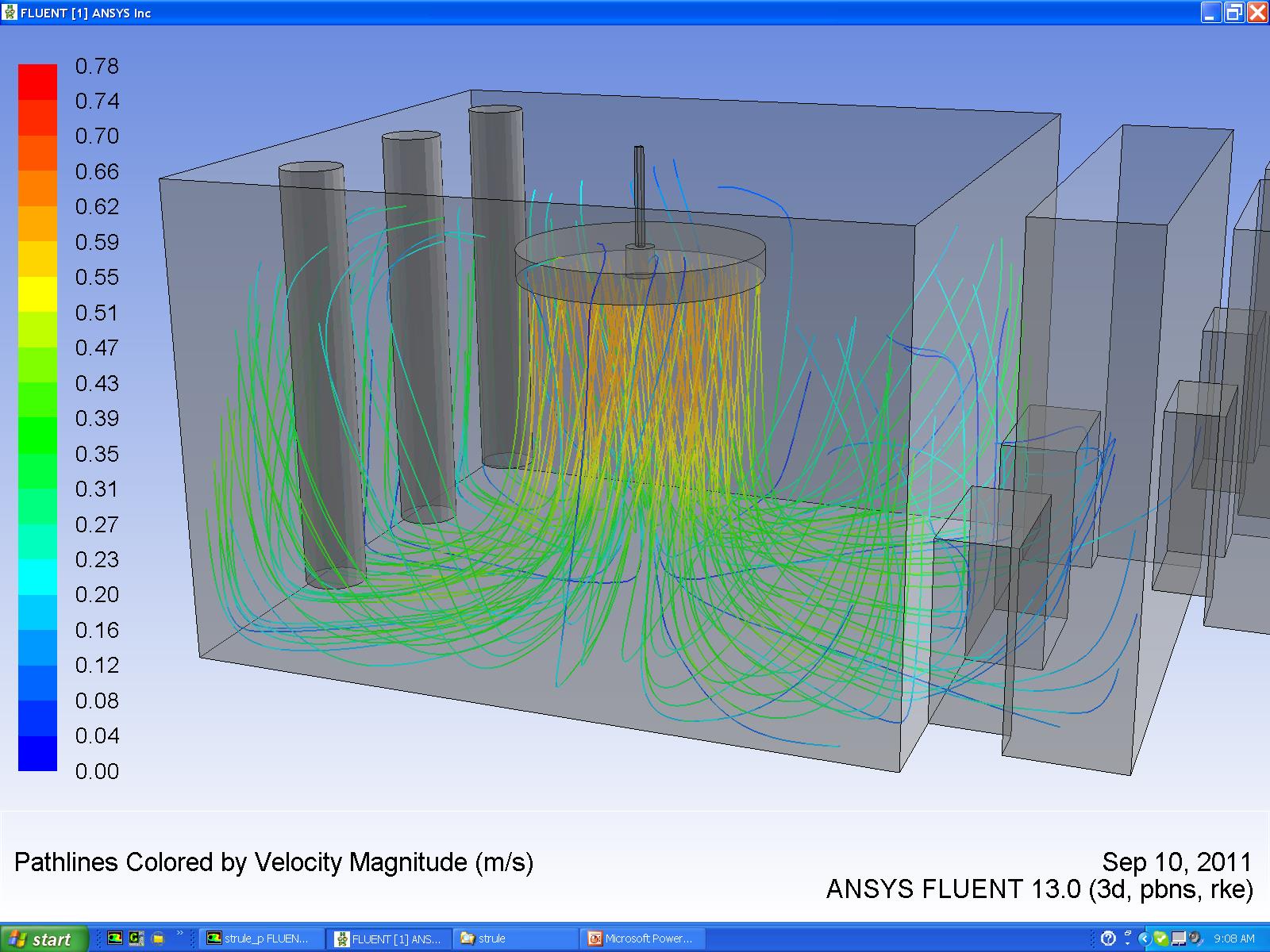

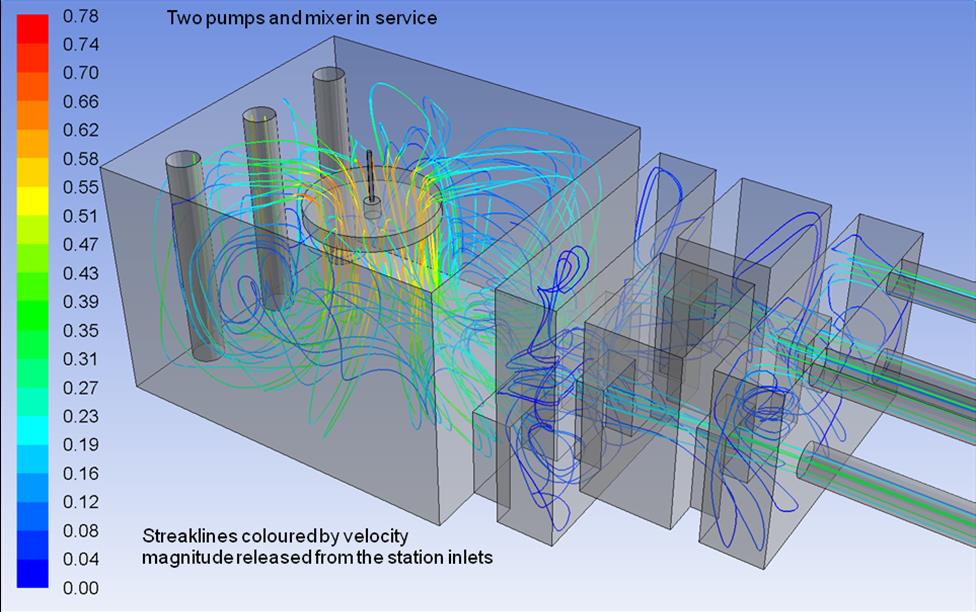

CFD analysis was considered the most appropriate course of action to fully understand the operating characteristics of the mixer and its interaction with deposited grits in the main sump. The CFD results illustrated that the correct scour velocities were achieved on initiation of the mixer; however, as noted on the physical model the location of deposition would result in debris transported back through the inlet ports and into the ported baffle chamber. CFD analysis also showed small areas of low velocities at the edges of the main sump regardless of pumped outflow.

Development

The development programme involved addressing the issues identified during the initial testing phase. To pre-condition flow on entry into the pump intakes and eliminate the sub-surface vorticity noted, a pump intake cone was developed located beneath the pump units. The proposed cone arrangement was very effective in eliminating the sub-surface vorticity and pre-conditioning the flow on entry into the pump intakes.

To deny low velocity and stagnation areas, infill benching within the main sump was installed. The initial testing programme noted low velocity areas immediately after the ported baffle located in the corners of the main sump, while the CFD analysis highlighted additional low velocity areas along the full perimeter of the sump. Introduction to the model of a small, 45º slope was introduced around the full perimeter of the main sump to eliminate the low velocity areas noted on the CFD analysis. In addition a large infill fillet located at the corners of the main sump local to the ported baffle wall was introduced to similarly deny low velocity areas.

A further area of infill benching was required within the upstream ported baffle chamber at the leading edge of the outlet. The area of infill benching was required due to the reverse flow observed from the CFD analysis. The benching will prevent any grits from settling within the ported baffle chamber, with transport to the main sump under normal operation.

Final Testing

A series of confirmatory tests were undertaken on the modified arrangement to confirm that the acceptable pump intake conditions could be maintained irrespective of operating range and pumped outflow.

Testing demonstrated that with the proposed modifications installed, a satisfactory pumping operating environment was achieved within the River Strule Abstraction Pumping Station. Pump intake conditions were free from submerged and surface vorticity with pre-swirl rotation maintained well within acceptable limits.

The study of grits determined that with the mixer in the current position debris is being forced back upstream and to overcome this, we re-located the mixer closer to the baffle wall to reduce the reverse flow into the ported baffle chamber and promote forward velocities to the two operating pump units. Provided that the mixer is situated in the relocated position with the duty and assist pumps in operation, any deposited grits should be re-suspended and transported towards the pump intakes.