SUPERYACHT LOAD OUT FACILITY

Client: SPP PUMPS LTDScale: N/A

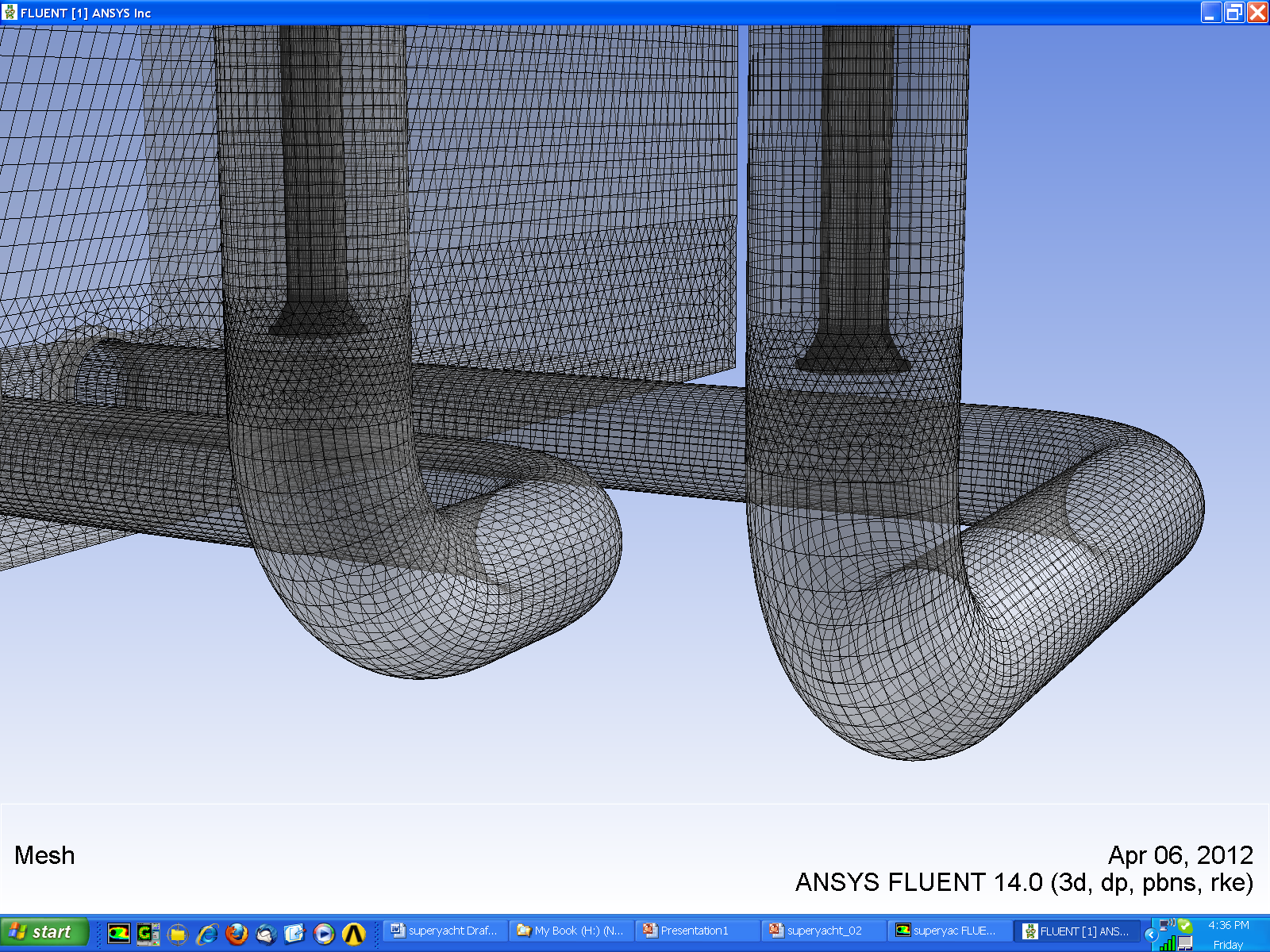

The pumping station for the super yacht basin at the Erhama Bin Jaber Al Jalahma Shipyard comprises three vertical turbine pumps. Each machine has its own 1.5m diameter inlet pipe feeding directly from the basin. Pump bellmouths are located approximately 3m below the top flanges of the inlet pipes. In the case of Pump 1, the inlet pipe makes one 90 degree bend from horizontal to vertical on its way to the pump. The lines for pumps 2 and 3, on the other hand, each have a two 90 degree bends, one horizontal and one vertical. The operating scheme for the pumps will be two pumps in service and one on standby.

The purpose of the model test is to establish the operating characteristics of the system and to develop the design, where considered necessary, to achieve a satisfactory hydraulic environment over the expected range of operating conditions. The pumps must operate in an environment where:-

Flow presentation to the pump intakes is acceptable.

Free surface and submerged vorticity are absent.

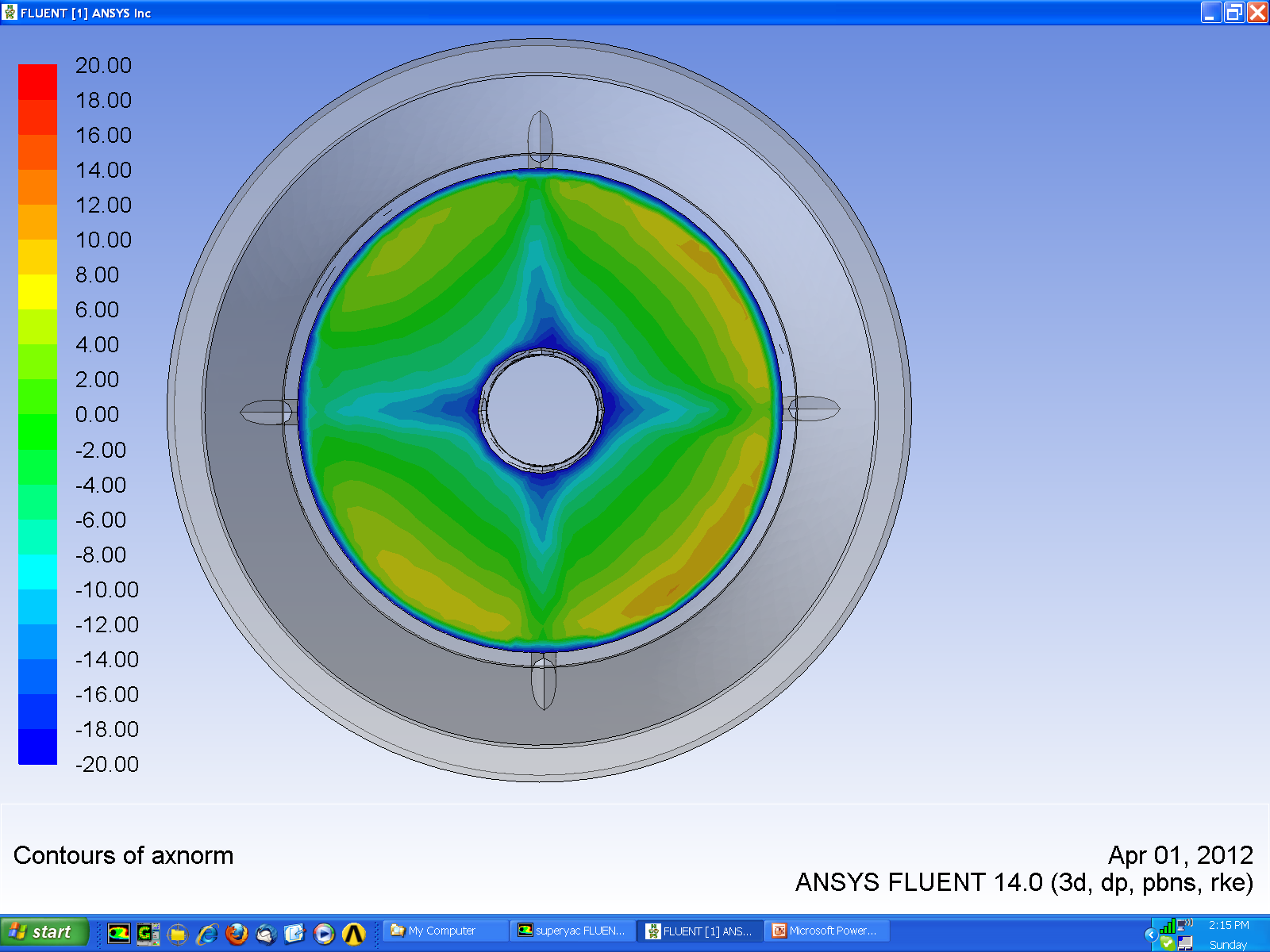

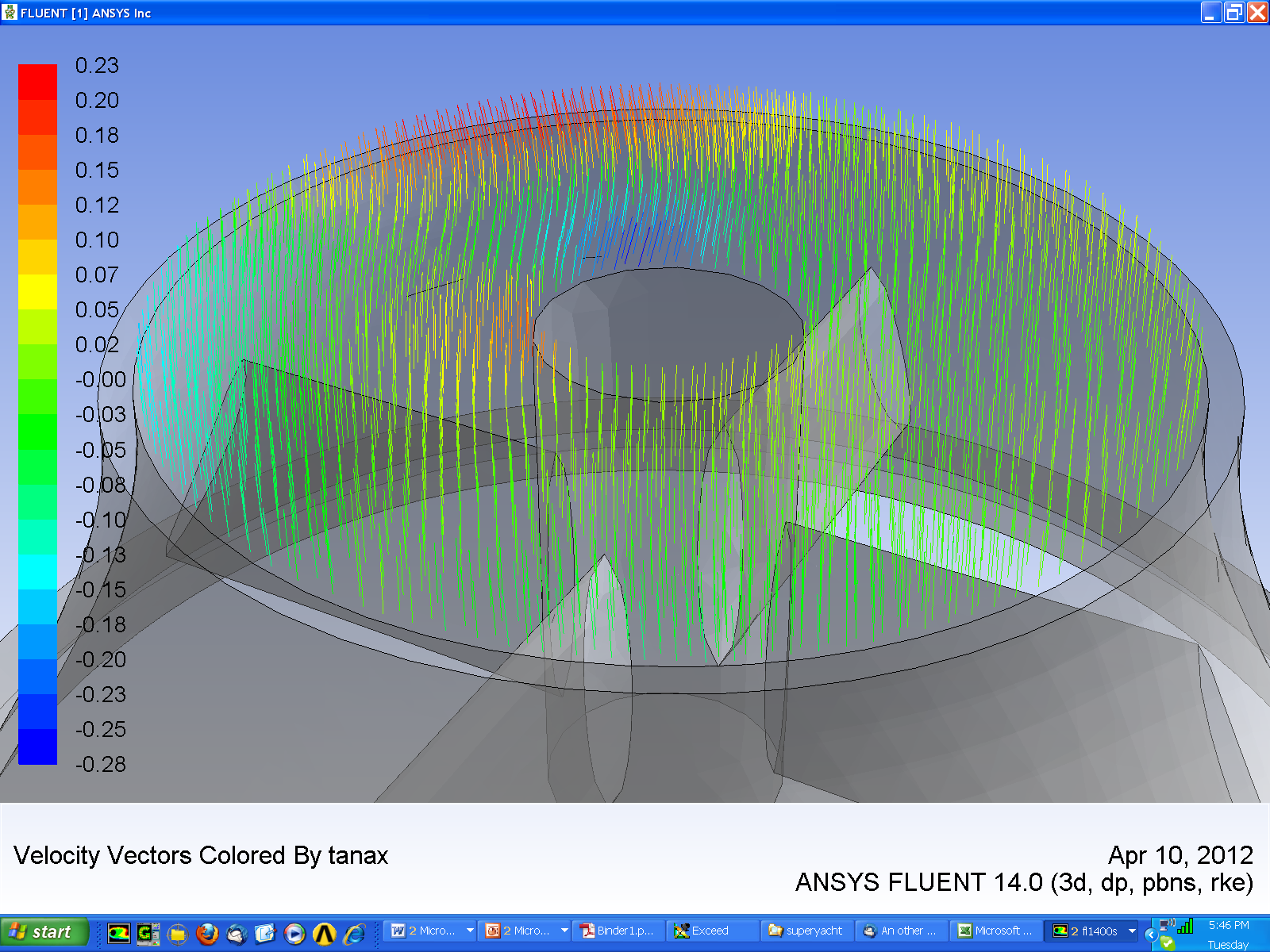

Pre-swirl rotation is within acceptable limits.

Initial testing

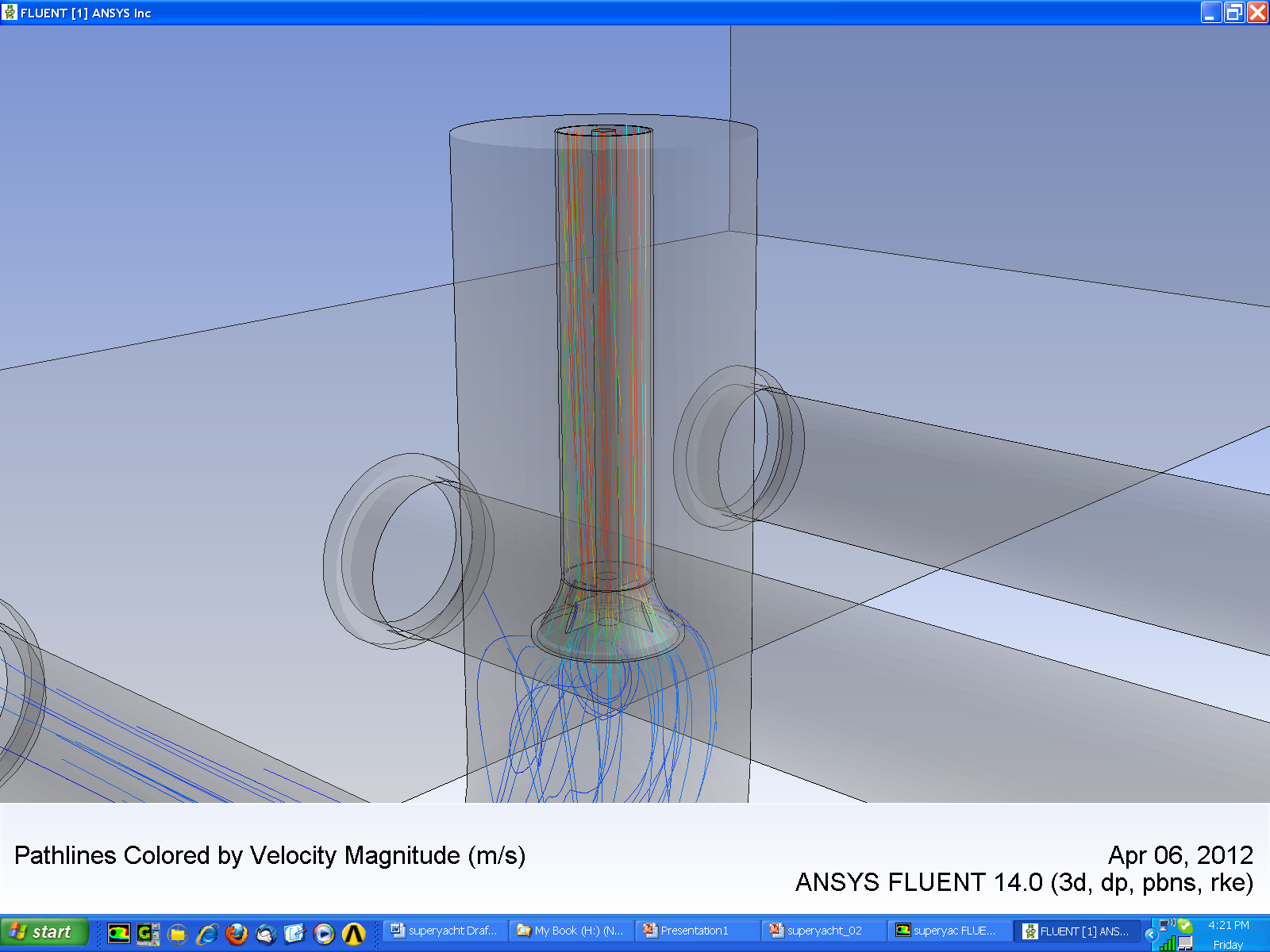

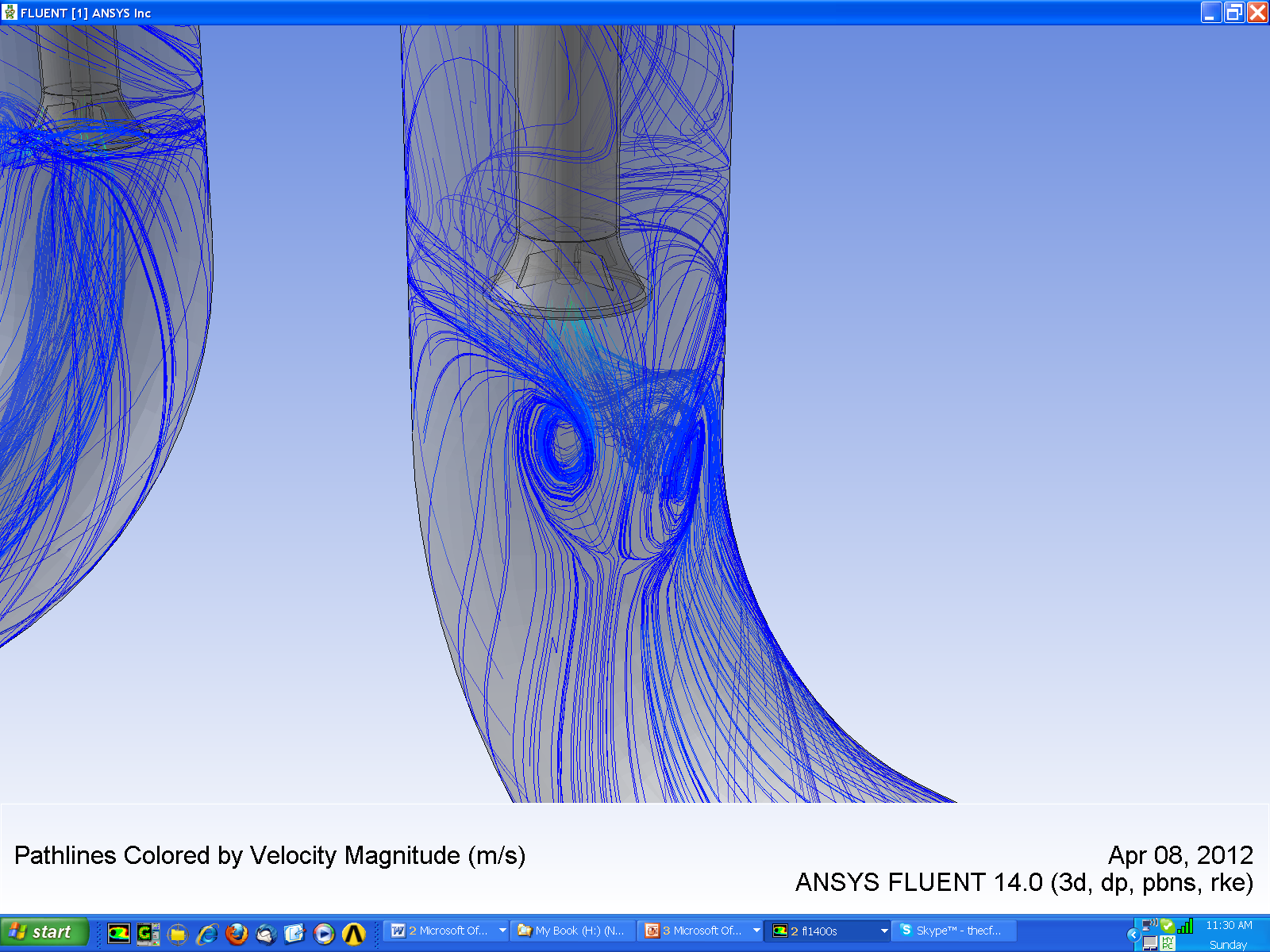

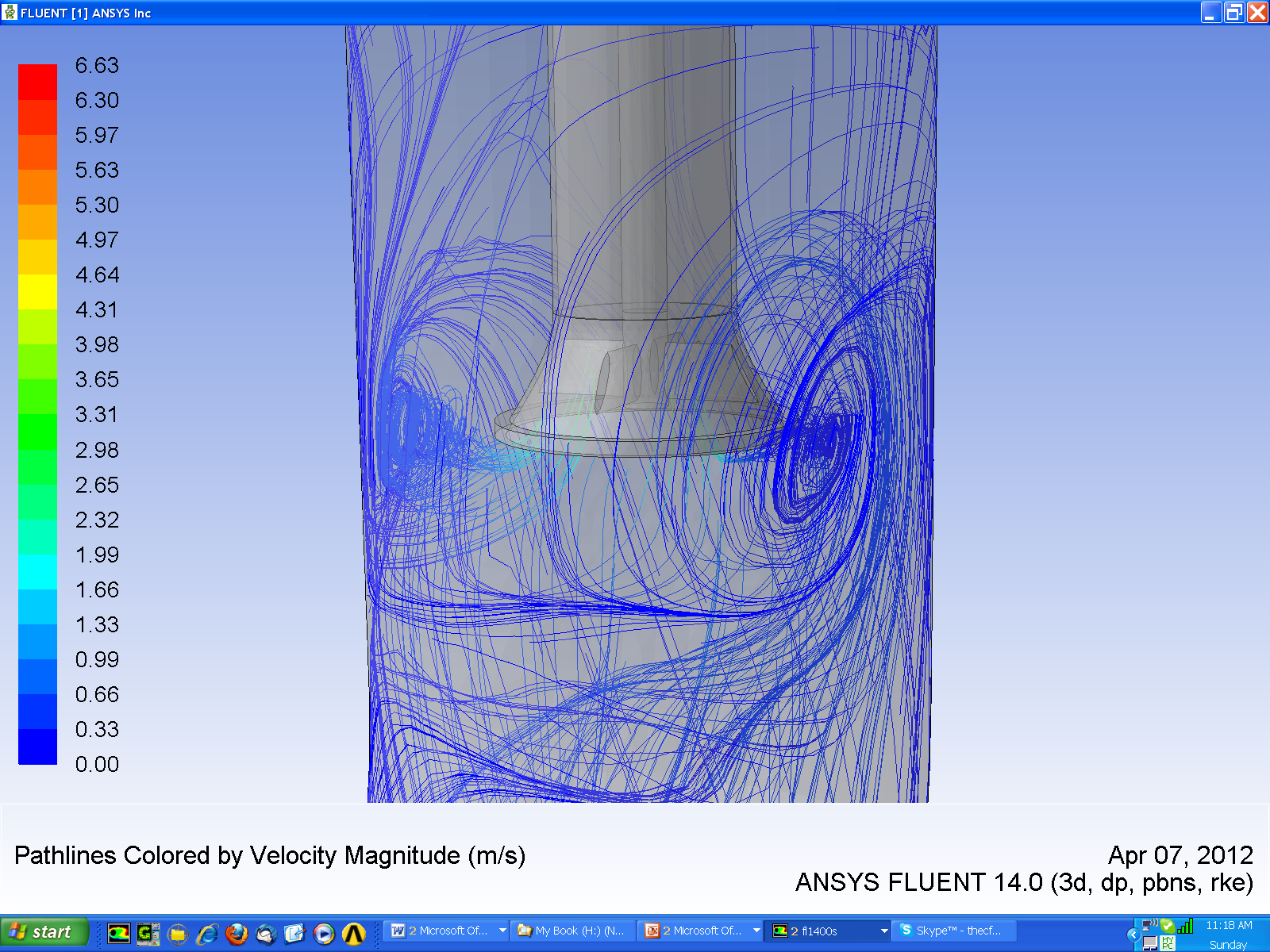

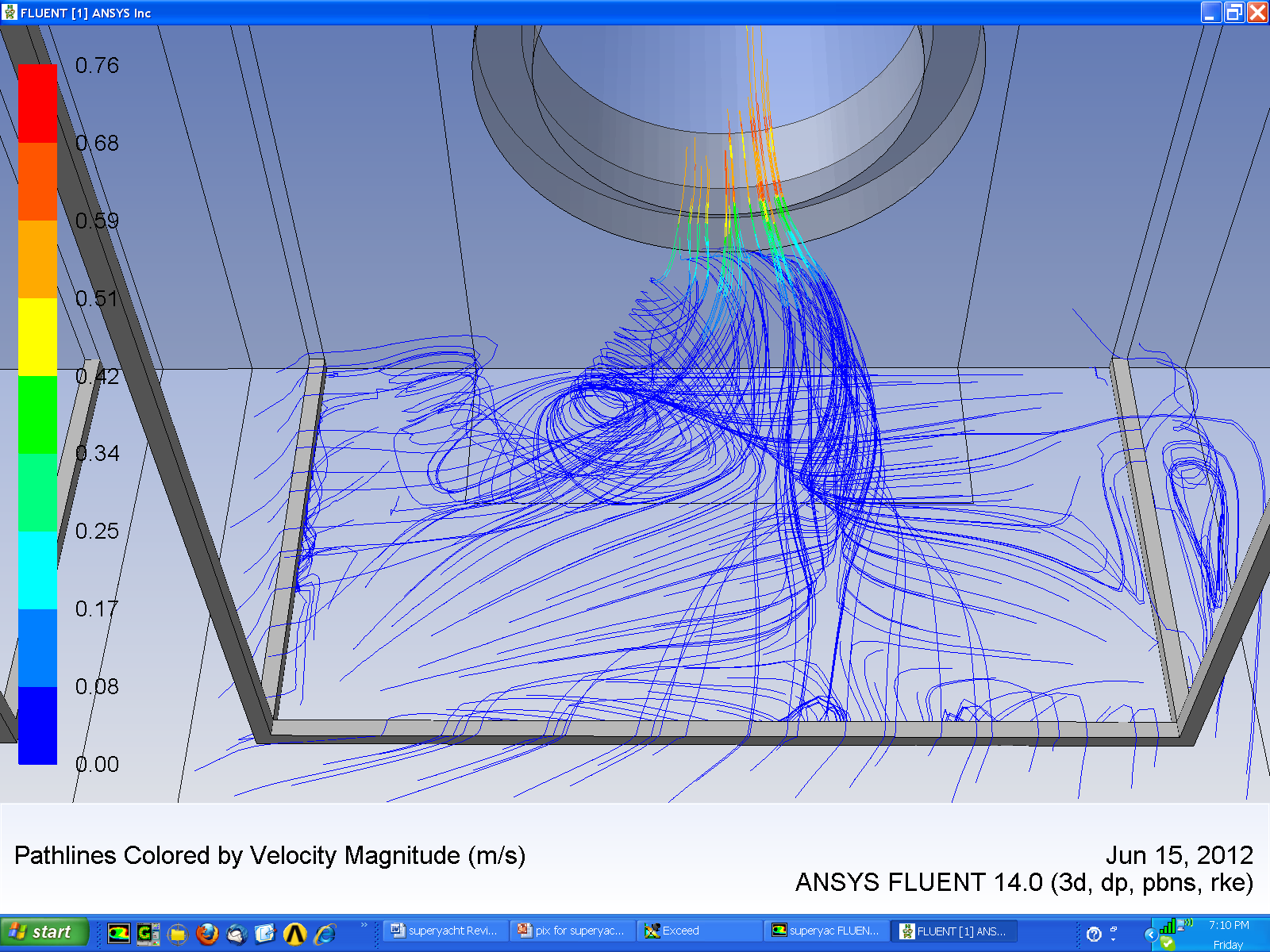

The initial testing programme identified areas of non compliance within the pump station. Measured levels for the pump inlet pre-swirl angle and velocity distributions were within acceptable ranges per industry standards. Evidence of vortices capable of reaching the pump inlets was observed for all three pumps, however. These vortices appeared to originate on the walls of the inlet pipes adjacent to the pump bellmouths. In these locations, velocities are comparatively low and there is considerable re-circulation into the annulus created by the space between the pump housing and the upper portion of the inlet pipe. This flow pattern, conducive to vortex formation, is consistent with all three inlet pipes.

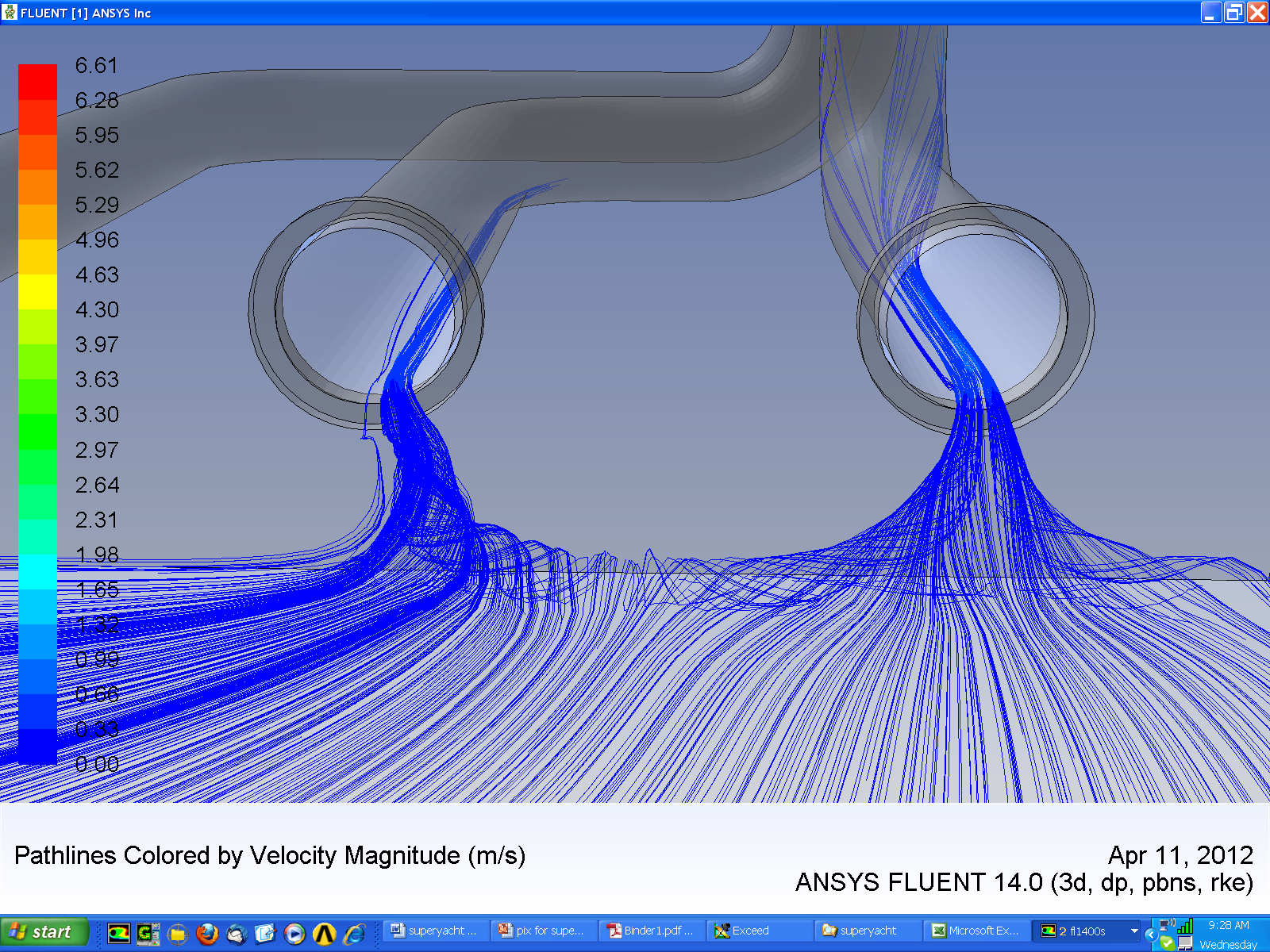

While no free surface vortices were identified, submerged vortices were observed forming on the floor of the chamber in front of the suction intakes as well.

Development and final testing - Submerged vorticity in the vicinity of the pump intakes

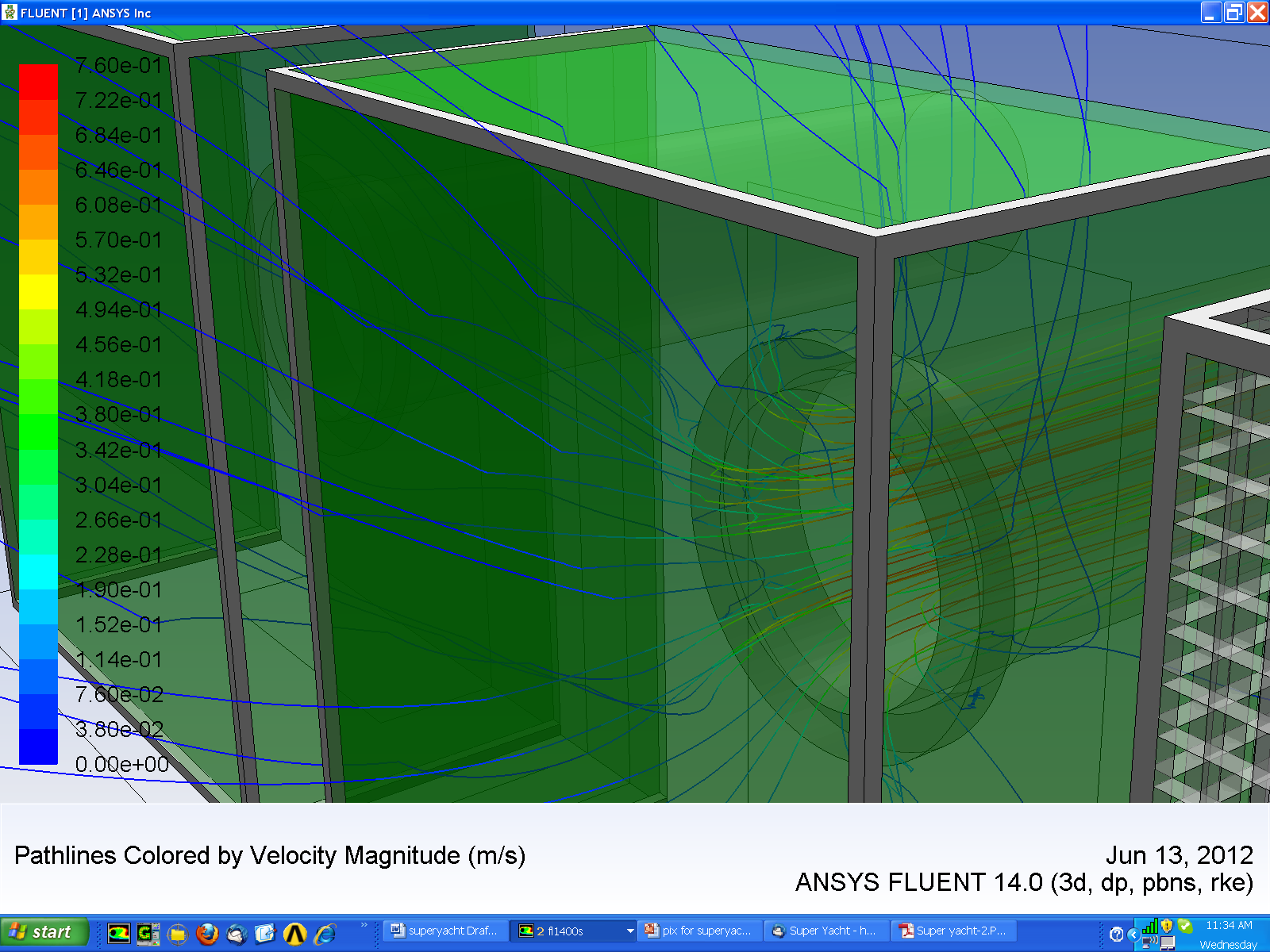

Some remedial changes to the station geometry are recommended to mitigate the effects of the submerged vortices forming on the walls of the suction inlet pipes. Discussions with the client confirmed that modifications to the suction pipes (in the form roughening ribs or similar) would be very difficult to install at this advanced stage of construction and operation. Therefore, modifications in the form of pump suction strainers that could be installed onto the intake bellmouth flange then lowered into the suction pipes were studied.

A conical shaped strainer proposed by the client was modelled. The strainer construction comprised a sheet metal conical shape with 50mm diameter perforations supported on a frame of 10x50mm bars.

The preliminary analysis of the flow in the vicinity of the pump inlets showed large recirculation zones downstream from the inside bend of each of the three supply pipes. The wall vortices observed in the initial testing were forming in these recirculation zones. The analysis following the retrofit with the perforated cone attached to the inlet bellmouth showed that the strainer was not effective in altering the flow pattern in the recirculation zone or the vortices that formed there. When the flow passed through the holes in the strainer, however, some flow conditioning was achieved.

Velocity distribution at the impeller position decreased from a maximum of approximately 10.43% to 7.19% above the mean value. Pre-swirl rotation was well within acceptable limits with levels just slightly changed from what was recorded during initial testing. In conclusion we would recommended that the conical diffuser is fitted to all pumps.

Development and final testing – Submerged surface vorticity in the basin

To prevent submerged vortices from penetrating into the pipe intakes, benching in the form of a splitter prism directly beneath the pipe intake proved to be an effective measure to counter the submerged floor vortices.