- SOUTH JEDDAH - AL KHUMRA SCREEN CHAMBER AND PUMPING STATION

- BRA 3494 – Sabesp Sao Lourenco, High Pressure Pumping Station

- FRANKLEY DE-ALK TRANSFER PUMPING STATION

- Deephams FTFT Pumping Station and Inlet Culvert

- Riverside Sewage Treatment Works - Regional Sump 1

- La Villette Pumping Station

- Bewsey Bridge Pumping Station

- Suez Thermal Power Station - Intake Pumping Station

- Norway Road Pumping Station

- Grimonpont RAS Pumping Station

- Nab's Head Storm Inlet Channel and Storm Pumping Station

Pumping Stations

FRANKLEY DE-ALK TRANSFER PUMPING STATION

Client: MWHScale: 1/3.3

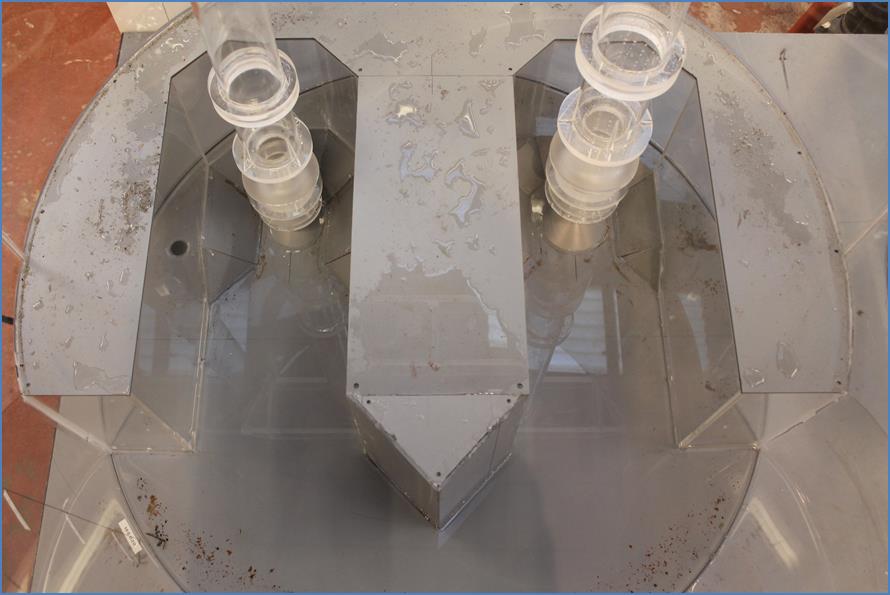

Frankley WTW is one of a number of Water Treatment Works operated by Severn Trent Water, where this works supports the water supply infrastructure in the West Midlands. The proposed Frankley WTW De-alk Transfer Pumping Station comprised of two 3.44m diameter sump chambers. Flow is delivered to each sump via twin 0.40m diameter inlet pipes which are cross connected to allow bypass in the event one of the sump chambers is off-line. Each sump will include an SPP pumps Ltd, vertical spindle pump unit, which will operate on a duty/standby basis. Two additional pumps will be installed into the sumps for future upgrade of the works capacity.

The purpose of the model test was to establish the operating characteristics of the system and to develop the design, where considered necessary, to achieve a satisfactory hydraulic environment over the full range of inflows, pump combinations and water levels.

Initial testing

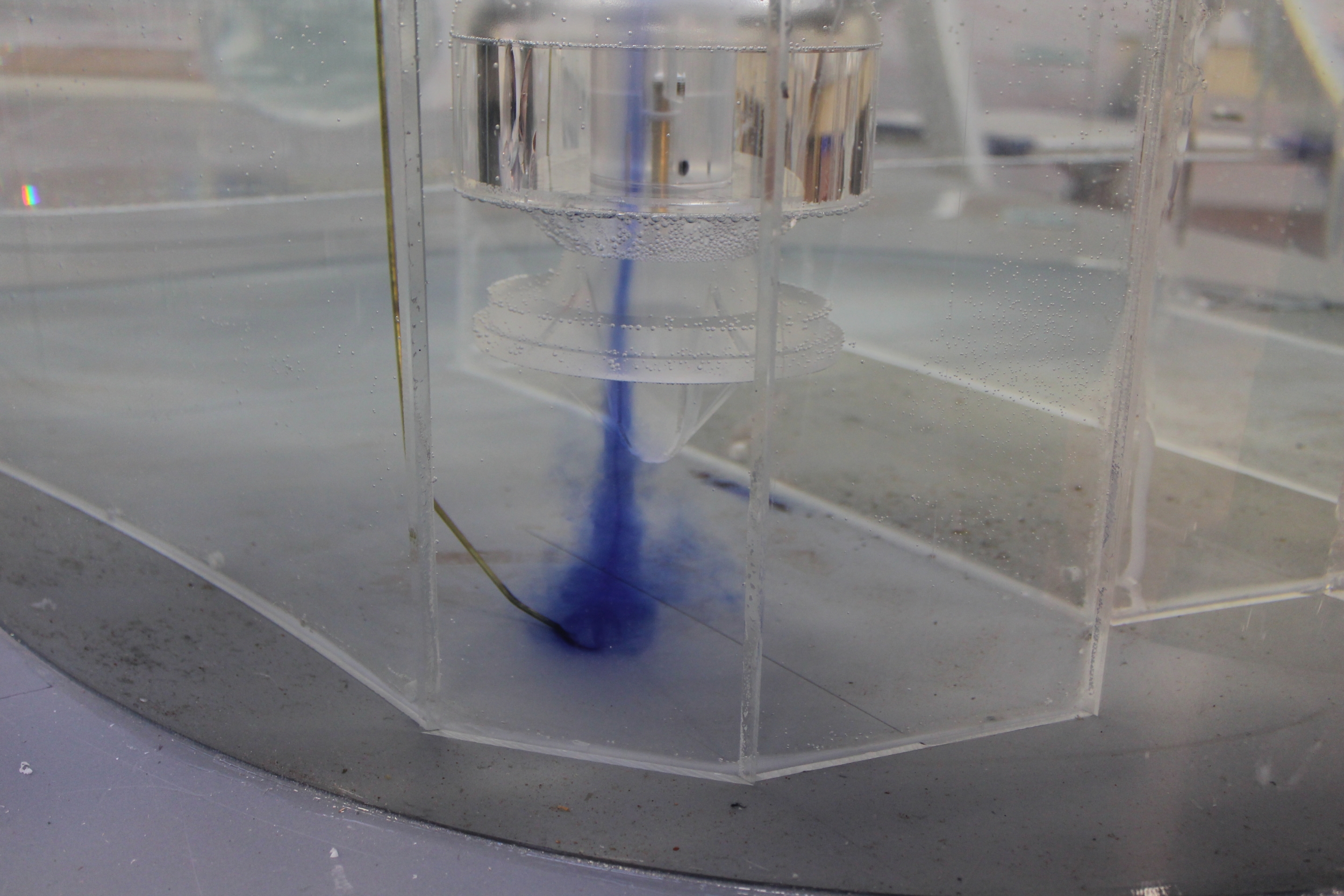

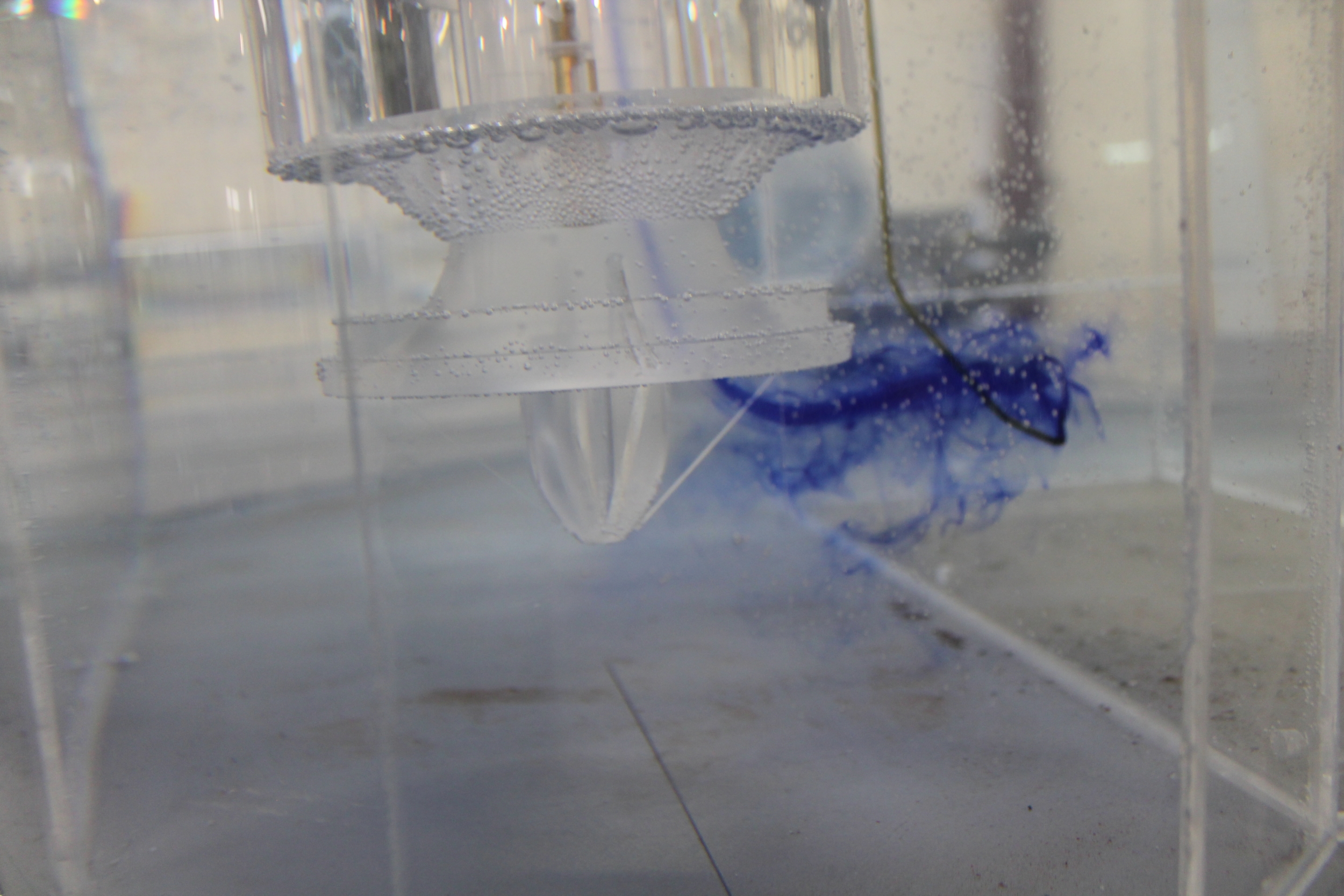

The initial assessment determined that the Frankley De-alk Transfer Pumping Station operated in an unacceptable environment. The installed pump units operated with the presence of coherent sub-surface vorticity throughout the level range, regardless of arrangement i.e., current or future.

Development

Following a review of the existing and future arrangements, several options were required to correct the adverse phenomena’s within the vicinity of the operative pump intakes. We would consider the following proposals to optimise the arrangement:-

- Triangular fillet installed on the central vertical face on the pump cell benching – Testing determined that flow exited the inlet pipe and interacted with the flat face of the benching creating a lateral spread of flow. It is proposed that the installation of the triangular fillet will promote a uniform approach velocity down each of the operative pump cells.

- Removal of the suspended baffle plate – The baffle plate was considered to accelerate the approach flow towards the operative pump units, as such; removal of the unit was undertaken.

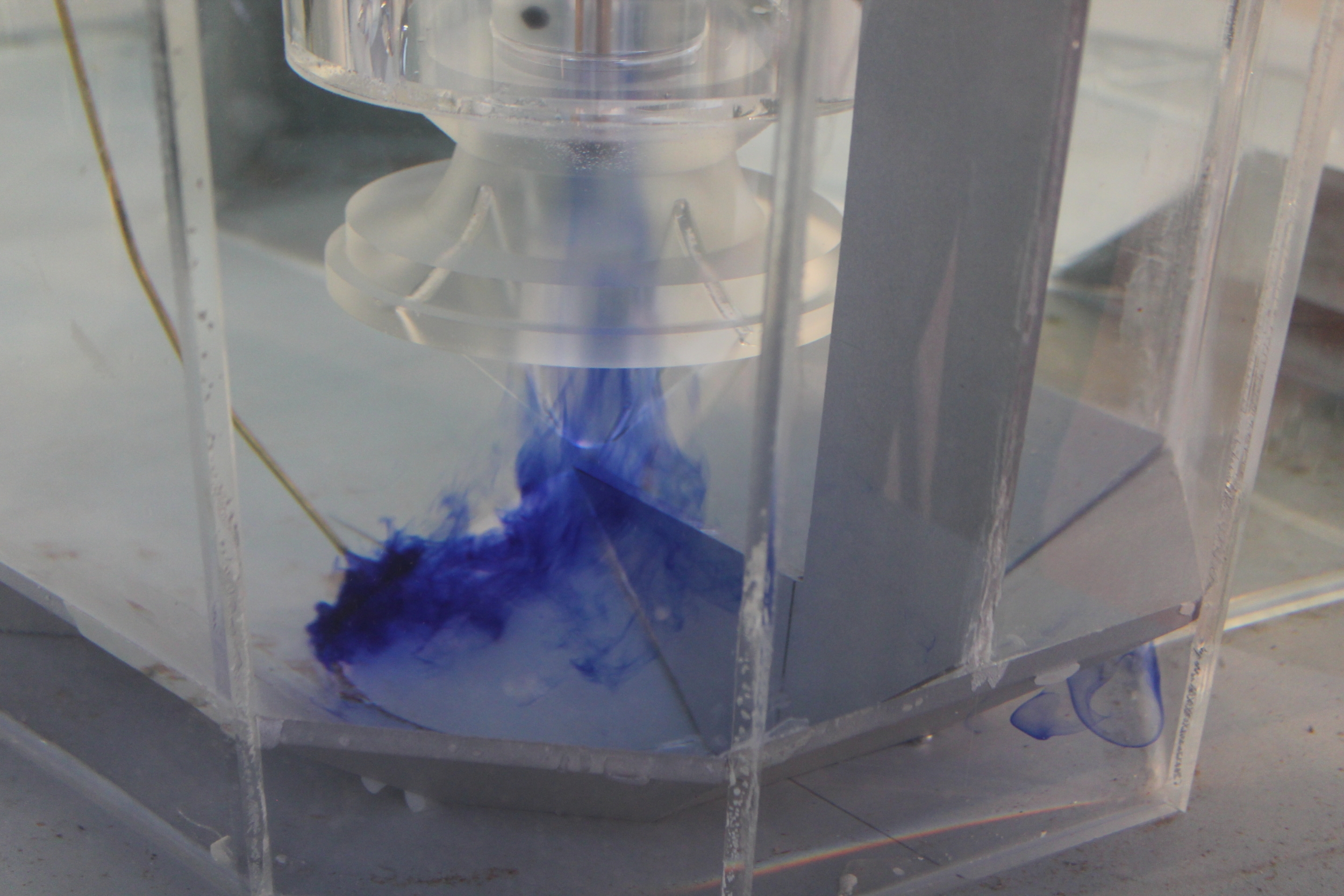

- Suction cone- Testing identified sub-surface vorticity forming off the invert of the sump and penetrating into the pump suctions. The suction cone is required under all suction intakes to promote a uniform velocity profile on entering the pump suction. The cone installed centrally, will suppress the coherent sub-surface vorticity observed throughout the initial assessment. The cone will also deny the vorticity a formation point, thus reducing the phenomena from forming.

- Profiled benching around the suctions- Testing identified that an excessive open area to the sides of the pumps, located within the cells allowed unstable flow to enter the pump units. It is suggested that the introduction of 45-degree infill benching part way down the cells to aid in streamlining the flow and provide a smoother transition into the pump suction intakes. Implementing this type of benching eliminated side wall vorticity as identified on the model within the previous testing section.

- Rear central vane – Testing determined that flow rotated around the rear of the pumps creating instability and swirl. The installation of the rear vane will eliminate flow from rotating around the rear of the pumps and promote a smooth radial intake around the full circumference.

Final testing

Following the adoption of the proposed modifications, the Frankley De-alk Pumping Station showed that a satisfactory operating environment could be achieved, in both sumps regardless of either the current or future arrangements. Testing also confirm that under bypass operation the station still exhibited acceptable conditions throughout.

Acceptable pump intake conditions were maintained under all anticipated station inflow rates and sump water levels. Pump intake conditions were free from surface and submerged vorticity, excessive jetting flows, the ingestion of entrained air with pre-swirl rotation maintained well within acceptable limits, as specified by the ANSI Standard recommendations of below 5.0 degrees. The swirl meter vanes were generally characterised by very minor bi-directional fluttering, which is indicative of stable flow passing the pump impeller position.

Final confirmatory testing replicated the bypass mode of operation, it was concluded that by altering the flow path via the inlet pipework no appreciable difference or deterioration in the approved environment was observed. As such, it was determined that with the installation of the proposed modifications bypass operation would still exhibit an acceptable operation environment.

The modifications proposed were kept as simple as possible and there was no requirement to alter the main structure or the position of the pumps. Testing on the physical model demonstrated that the arrangement was fully optimised with the adoption of the proposed modifications, no further improvements are considered necessary.